The Dangers of Biofilms: Contamination and Corrosion

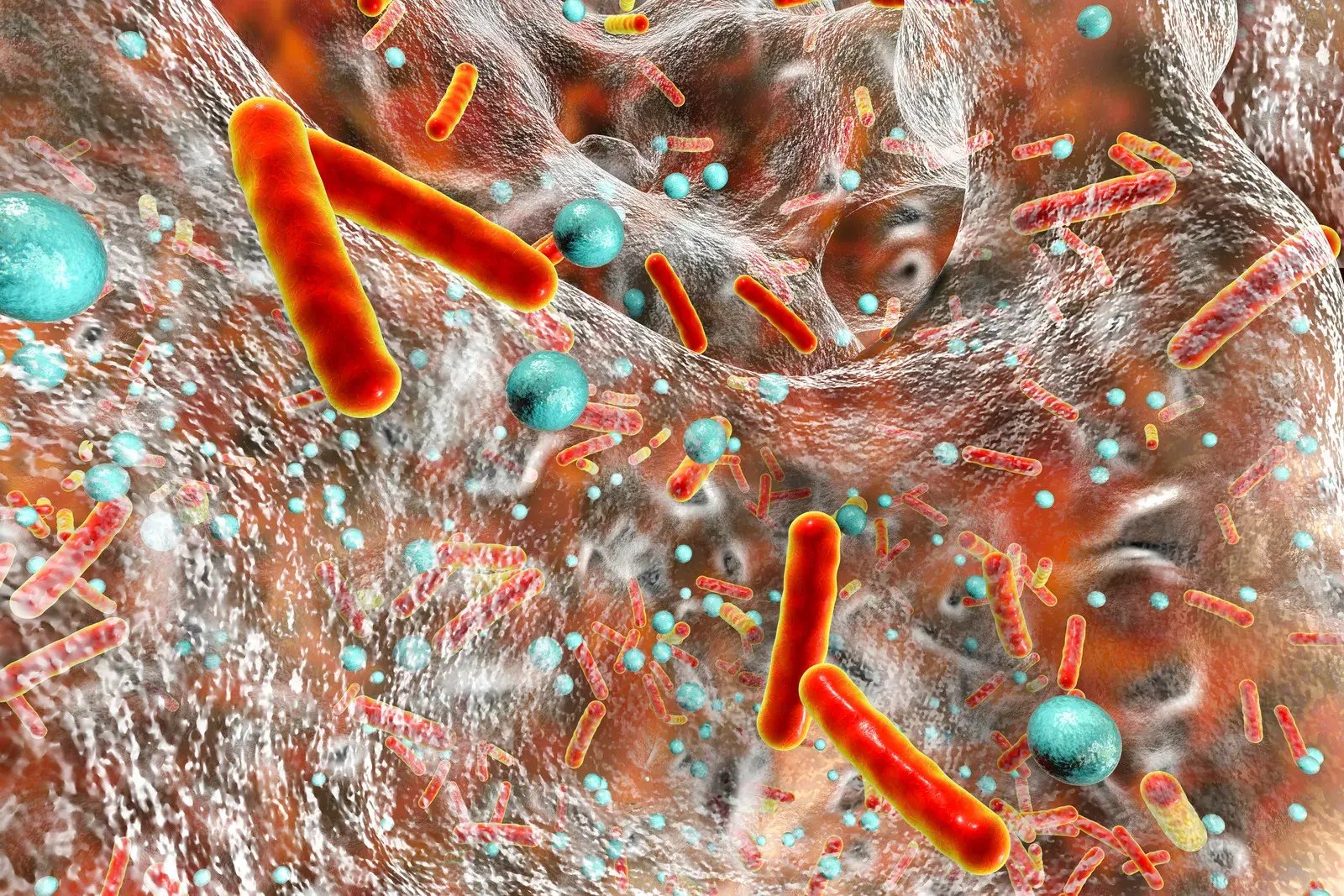

A biofilm is often made up of various different types of bacteria – all held together by a extracellular matrix (EPS) – or “slime”. If undetected and allowed to develop, they can become quite complex and difficult to remove.

Aside from causing the obvious biological contamination to your products, biofilms can also cause severe corrosion of your system with microbiologically induced corrosion (MIC).

INOX Passivation utilise a multi-stage approach to biofilm removal, as to maximise the chance of fully eradicating it – along with any by-products that may have formed along the way.

Frequently Asked Questions

Due to the often complex nature of the way biofilms develop, we have had the most success when using a multi-stage approach to removing it. Our standard process includes four stages, each using very different chemistry. As such, it tends to take a little longer than our other chemical cleaning processes.

To perform our standard biofilm removal process on a typical purified water loop, we would need 2 days.

It depends on what the root-cause of the biofilm was. If the biofilm was introduced by outside contamination (i.e., during an intrusive one-off inspection), it shouldn’t come back. Likewise, if the biofilm formed on rouge that had been allowed to develop, it shouldn’t come back (our biofilm removal process includes a stage to remove rouge). However, if the biofilm is allowed to form as a consequence of poor system design (dead-legs, insufficient flow, poor surface finish, etc.), there is a chance that it will come back at a later date.

Speak To An Expert

Submit A Question Or Enquiry And Speak To One Of Our Experts To Find Out More!

Submit an enquiry with your question, to give us a brief or to request a call back from one of our experts.

When you get in touch with INOX:

We'll contact you back as soon as we are able to

We'll always aim to provide 'best advice' for your business

We offer a free initial consultation

Your information is treated in the strictest confidence

You can ask us for advice or help on any or all of the following:

- Passivation

- Derouging

- Oxygen Cleaning

- Biofilm Removal

- Riboflavin Testing

- Pre-Commissioning Flushing

- Carbon Steel Pickling

Simply confirm your details on the form provided and we'll be in touch ASAP. We look forward to hearing from you!

From Our Blog

Benefits Of Stainless Steel Pickling In The Power Generation Industry

Rouge Types: What Are The Three Main Classes Of Rouge?