Understanding The Differences Between Derouging And Passivation

by Neil Brook on July 30, 2024

Stainless steel is the material of choice for a lot of industrial equipment, due to its durability and strong resistance to corrosion. However, to maintain these properties and sustain surface quality, many stainless steel applications require regular derouging or passivation.

What Is Passivation And Its Purpose In The Food & Beverage Industry?

by Neil Brook on July 16, 2024

It goes without saying that, in the food and beverage industry, it is essential to maintain hygiene and efficiency.

Rouging and Derouging: Stainless Steel Chemical Cleaning

by Neil Brook on May 21, 2024

Rouge is made up of a variety of iron oxides (rust). It is important that corrosion products (rust or rouge) are not present in your manufacturing and distribution systems, tanks or equipment.

Rouge: What is it?

by Neil Brook on May 7, 2024

Rouge is a common problem in pharmaceutical facilities, most often found in high-purity water and clean-steam systems fabricated in austenitic stainless steel.

Passivation Of Stainless Steel

by Neil Brook on April 8, 2024

Introduction There are many industries that demand high-purity systems in which they can manufacture their products (pharma, food, cosmetics, semi-conductor, etc.) or whose processes are carried out in hostile environments and need to be assured that their equipment is up to the task …

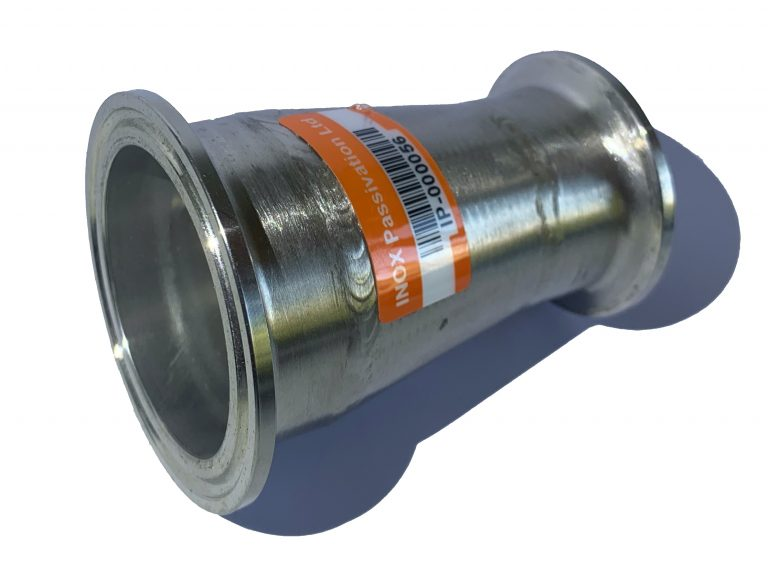

Preferred Pickling and Passivation Providers

by Neil Brook on March 20, 2024

INOX Passivation Ltd specialises in the onsite pickling and passivation of pipework and vessels by circulation, and the spray-pickling of large fabrications. This year (2020), we have pickled and passivated a 1.5 km pipeline for one of the worlds largest chemical producers, and comple …

Optimising Your Chilled Water / LPHW Loops

by Neil Brook on March 6, 2024

Many processes within your plant depend on effective chilled water and low-pressure hot-water (LPHW) systems. These are typically constructed from carbon steel pipework and circulate water / glycol with the addition of a corrosion inhibitor.

Dynamic Flushing

by Neil Brook on February 14, 2024

The photos show the debris we captured during the pre-commissioning flushing of a purified water system. (3” pipework, 35m3/hr flow-rate, 50 micron strainer).

Prevention of Contamination - Supplier Selection

by Neil Brook on June 16, 2020

Ordinarily, the main reason for having a chemical cleaning contractor on your site is to either remove a form of contamination from your equipment, or as part of a pre-commissioning activity to ensure your equipment is in optimal condition for service. It is therefore, of the utmost i …

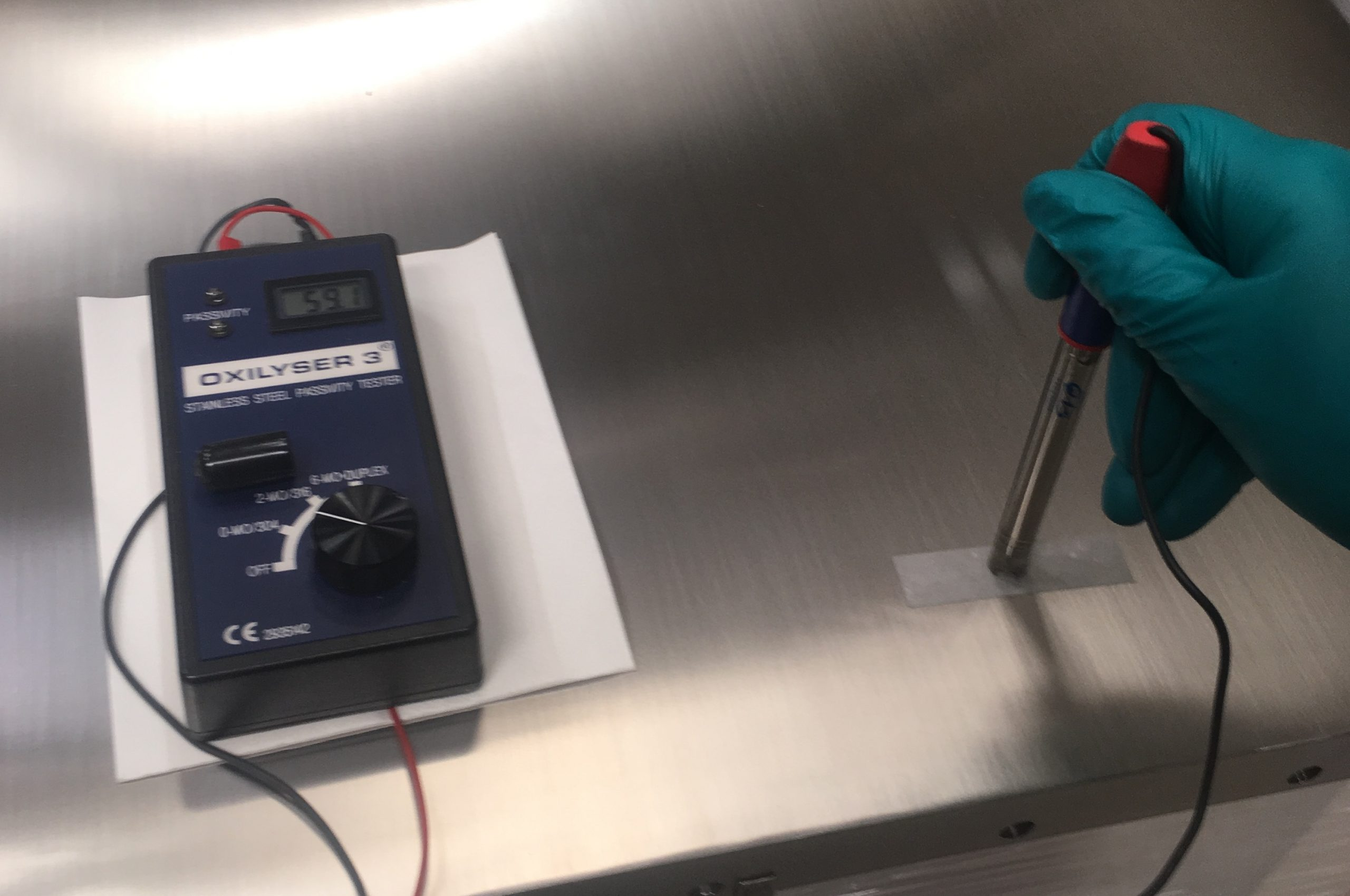

Three Ways to Test the Surface Cleanliness of your Stainless Steel

by Neil Brook on April 29, 2020

Stainless steel gets its corrosion-resistant qualities from the chrome-oxide (passive) layer that forms spontaneously when it comes into contact with atmospheric oxygen. This protective layer is extremely thin and in order to fully form, the stainless surface must be thoroughly cleane …