ASTM A380 ‘Practice for Cleaning, Descaling, and Passivation of Stainless Steel Parts, Equipment and Systems’ defines pickling as a chemical treatment using strong, corrosive acids that remove metallic contamination, welding and heat-treatment scales.

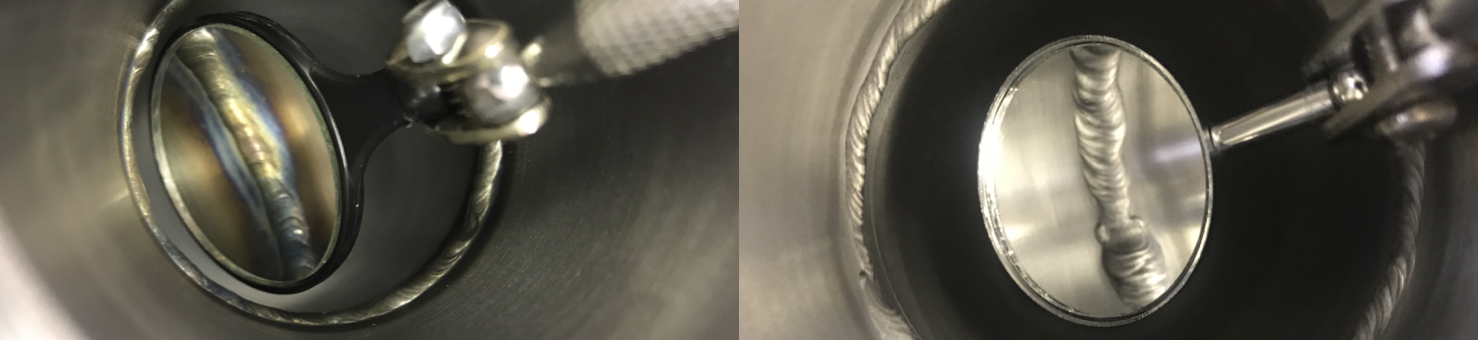

Unlike chemical passivation, acid pickling will etch the surface of the stainless steel, removing material. Because of this, we would not recommend the pickling of polished or machines surfaces. A pickled surface is usually a uniform, matt-grey colour with all traces of weld-heat-tint fully removed. Whereas, passivation has no effect on the cosmetic appearance.

As with other chemical cleaning processes (degreasing and derouging for example), pickling is a means of cleaning the stainless steel surface from contamination, creating the best conditions for effective passivation.

If your stainless steel will be used in a corrosive or hostile environment, pickling and passivation is essential. It is the best method of ensuring your components go into service free of contaminants and to ensure that the vulnerable areas adjacent to any welds have been restored to the alloys natural levels of corrosion resistance.

Successful pickling is a function of acid strength, acid temperature and contact time. All three variables can be manipulated (within reason) in order to suit the grade of stainless steel, the component being processed and of course, the client’s schedule.

Pickling can be performed by immersion, circulation, spraying or brushing. Typically, smaller items are immersed and larger items are sprayed. Fixed pipework and vessels can be circulated through. The design of the component will usually dictate which process is used. For example, it may be prudent to spray a small, complicated fabrication rather than to immerse it – where it is at risk of acid entrapment, formation of air-pockets and handling damage.

The grade of stainless steel / duplex should be taken into consideration, as well as the severity of discolouration in the heat-affected-zone and/or other contaminants. We adjust the chemistry of our pickling products to suit individual projects as to be able to remove contaminants without adversely affecting the base material. This includes the special formulation of a nitric-free solution which enables us to safely heat the pickling chemicals to much higher temperatures, dramatically reducing the required contact times on super-duplex projects.

Pickling products are toxic and should only be handled by trained and competent staff. Suitable safety and environmental controls should be in place throughout the process, including the subsequent capture and disposal of hazardous waste. This is particularly important when carrying out work on a client’s premises as it is unlikely that they have got suitable control measures in place for this type of activity. Temporary equipment and systems will be essential to ensure that personnel and the local environment are protected. A registered waste transfer/disposal company will be brought in to remove the spent chemicals and rinse water once the project is complete.

INOX Passivation Ltd operatives have NEBOSH, IOSH and various other health and safety qualification. In addition, we are trained in cGMP, FMEA and other related topics, ensuring that the work we carry out conforms with all applicable regulations and satisfies your own QHSE Management Systems.